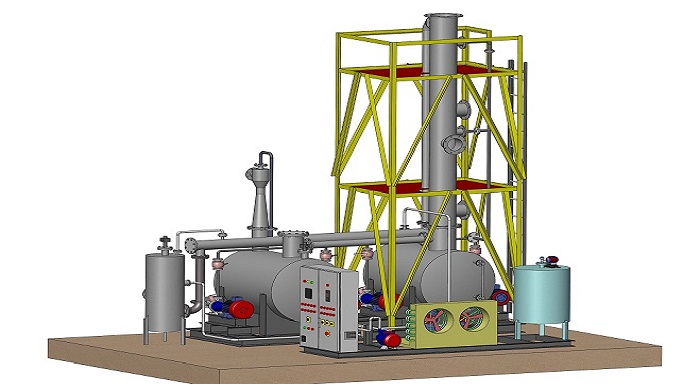

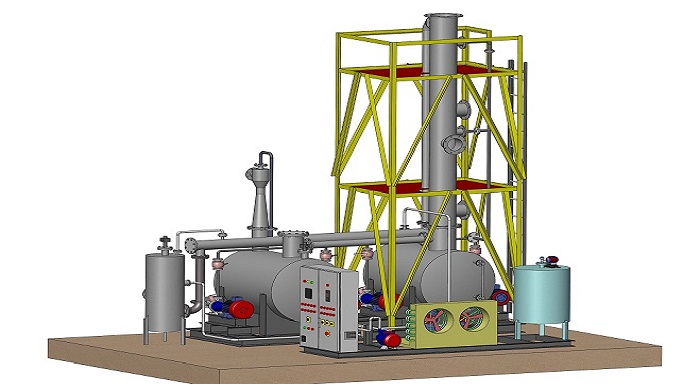

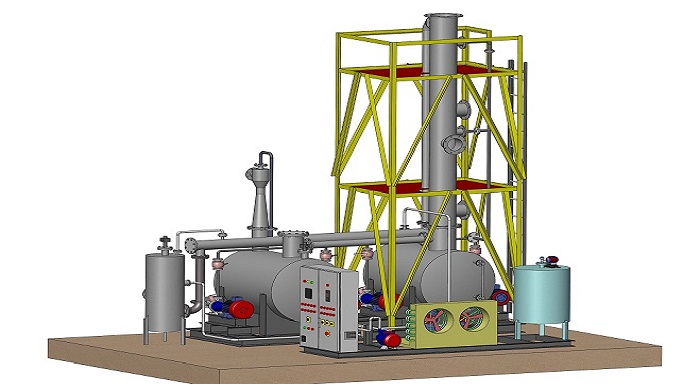

Hydrogen Sulphide (H2S) Scrubber System:

General:

In recent years, there has been growing interest in biogas an energy source from biodegradeble product . However, in many agricultural countries, agricultural waste is often the problem of environmental pollution because of presence of high contents of H2S in biogas which is very toxic and corrosive in nature.

Biogas is produced by the anaerobic digestion or fermentation of biodegradable materials such as biomass, manure, sewage, municipal waste, green waste, plant material, and crops. Biogas comprises primarily methane (CH4), carbon dioxide (CO2) and small amounts of hydrogen sulfide (H2S), moisture and siloxane. Depending on the origins of the gas and the kind of biomass, there are many different names such as: swamp gas (wet gas), marsh gas (moist gas from plants), digester gas (compressed gas), and landfill gas (including 50% methane, 45% carbon dioxide and 5% other gases).

Need For Hydrogen Sulphide Removal:

Hydrogen sulfide (H2S) is a colorless, very poisonous, flammable gas with the characteristic foul odor of expired eggs, when combined with water creates sulfuric acid. Sulfuric acid is the corrosive acid, which corrodes the metallic parts like Boiler tubes, Engines coming in contact with it in few hundred hours of operation ,causing holes corrosion and brittle cracking of metal due to hydrogen, which can lead to breaking of the tanks or piping.

In many agricultural countries, agricultural by-products are often the problem of environmental pollution and affect human health. The biogas systems have contributed to provide energy for daily life, limited waste and offered many realistic applications. However, burning H2S in biogas will form sulfur dioxide, which causes environmental pollution.

Therefore, the removal of H2S is a critical issue, encouraged to protect the device, enhancing safety for technology systems.

About Chemical Scrubber:

Absorption is basic chemical engineering operation and is most preferred and well established gas pollution control technique.

Bio gas scrubber based on Caustic (NaOH) Treatment is well popular for their advantages which are unparalleled as compared to other

scrubbing methods.

The Biogas is first washed in Venturi to remove the suspended particles /foam etc, further it goes in to the Chemical Treatment into the packed tower.The Scrubber is so designed that the spent Li life is used to the last possible extent resulting in very low casting consumption and estimated saving of 25-50% can be achieved depending upon Biogas Composition and H2S levels.

GGE provide fully Customized & Cost effective Solutions as per the Project requirements.

Main features:

Appllications: